MS CHANNEL (ISMC)

MS CHANNEL (ISMC)

MS channels, also known as C-channels or U-channels, are widely used structural elements in construction and engineering due to their strength, durability, and cost-effectiveness. They are commonly employed for structural support, scaffolding, purlins, and various other applications

MS channels are commonly used in construction, shipbuilding, machinery, and various other industries where strong and reliable support is needed. They are also used in material handling systems, bridge construction, and other structural applications

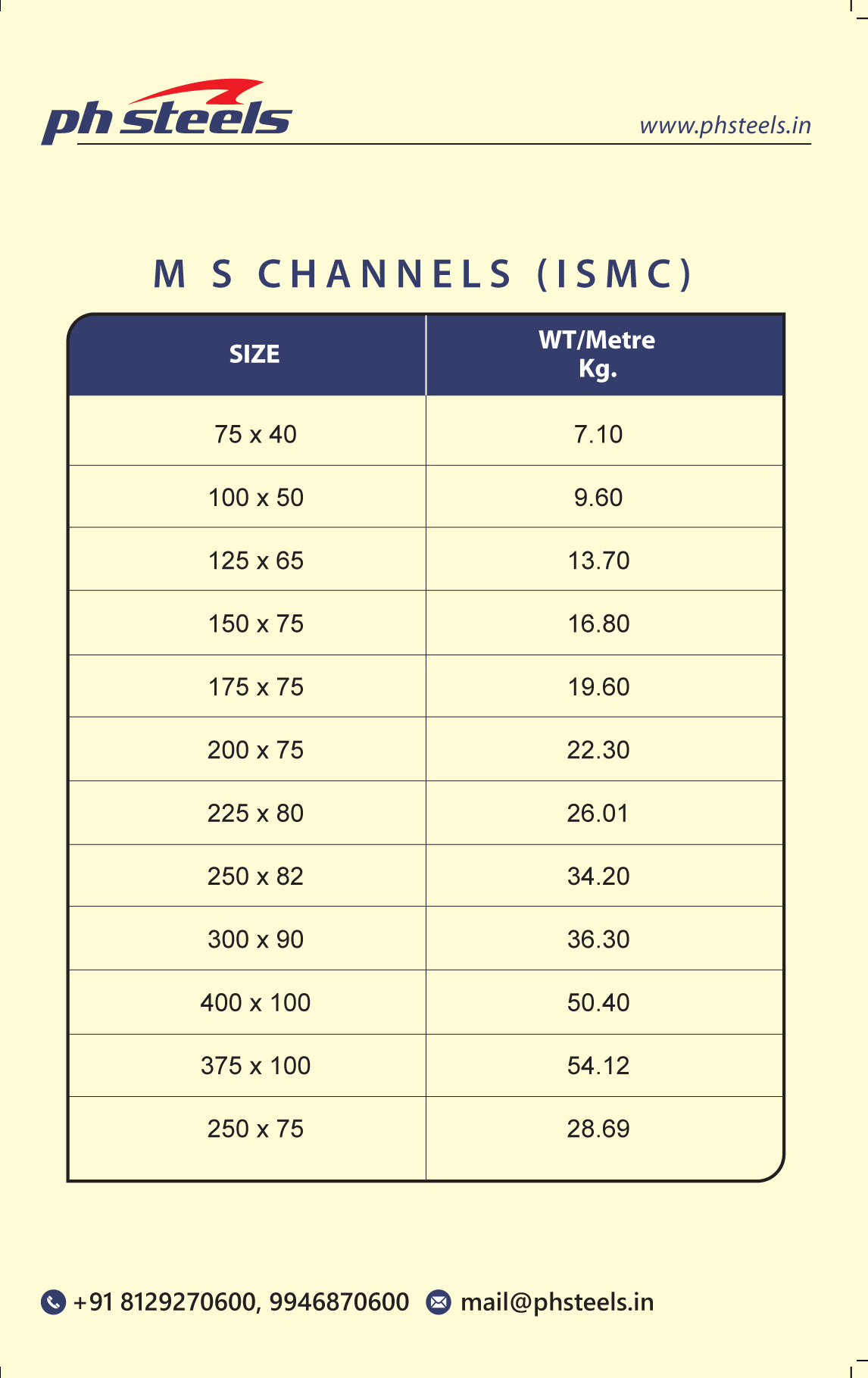

Specification

Key Features

- Material Composition: Made from mild steel (MS), known for its ductility, weldability, and affordability.

- Shape and Cross-Section: C- or U-shaped cross-section with a web and two flanges for structural strength.

- Standard Sizes: Available in ISMC sizes like ISMC 75, ISMC 100, ISMC 150, etc., defined by height × width × thickness.

- High Load-Bearing Capacity: Can support heavy loads and resist bending and shear forces.

- Versatility: Used in a wide range of applications including construction, fabrication, and industrial frames.

- Durability: Strong and long-lasting; can be galvanized for enhanced corrosion resistance.

- Ease of Fabrication: Easy to cut, drill, weld, and shape using standard tools.

- Cost-Effective: Offers a good balance between strength and cost, making it economical for large-scale use.

- Surface Finish Options: Available in mill finish (black) or galvanized form for specific environmental needs.

- Standard Compliance: Manufactured according to IS 2062 or other standards ensuring quality and uniformity.